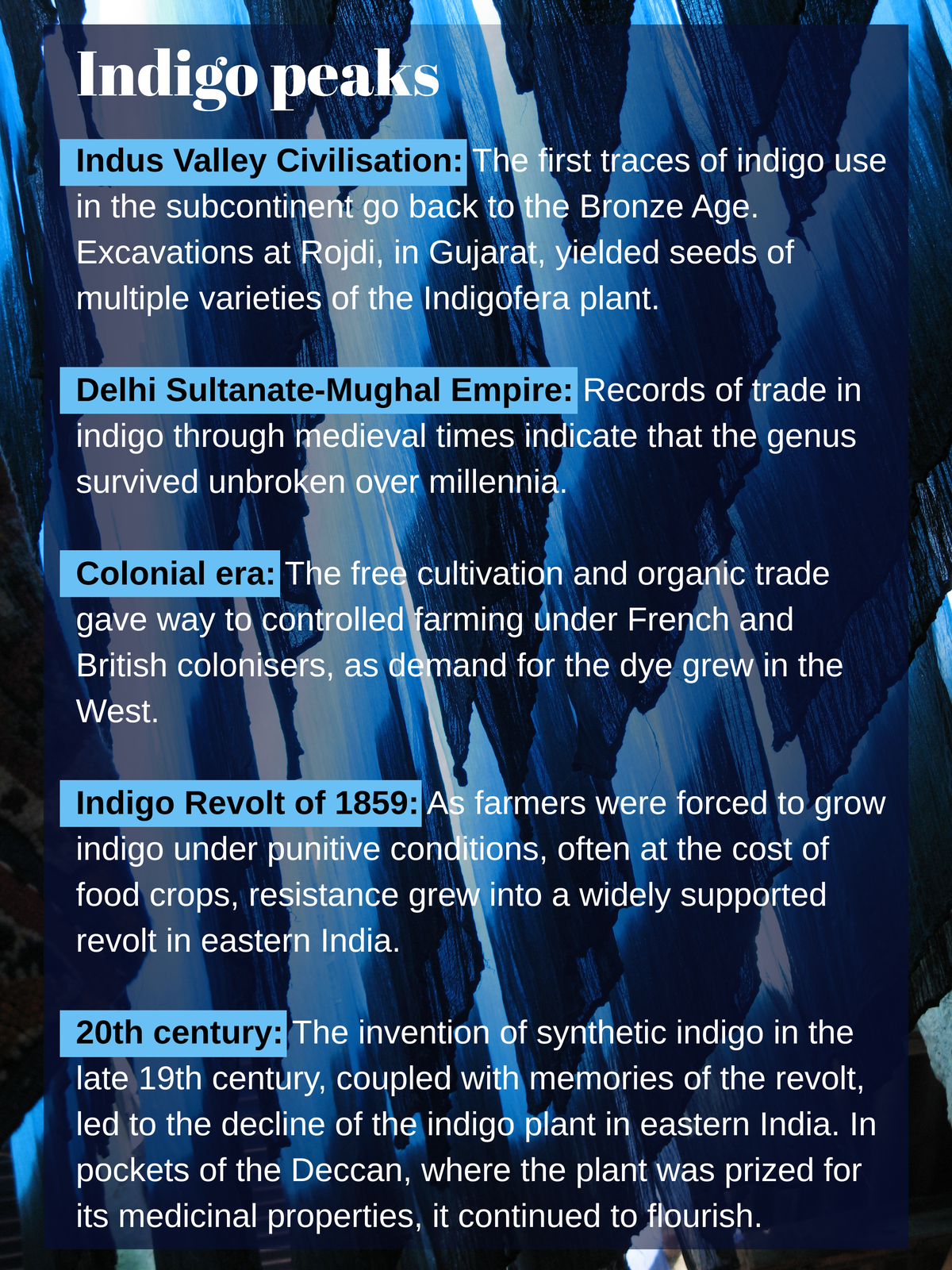

In a room well beyond the Blue Futures: Reimagining Indigo exhibition at Hampi Art Labs stands a large plastic vat, wrapped in a bright red-and-black tartan blanket. Night temperatures in Vidyanagar, the Jindal South West (JSW) township at the edge of which the art gallery and residency are situated, drop to about 16°C and that vat of indigo is as precious as a baby in the eyes of all the artists in attendance.

So much so that the first display the visitor encounters at the exhibition is a vat of the blue dye. Meera Curam, the curator of the show, removes the lid with a flourish, allowing us to gaze at the floating ‘flower’, a coalesced skin formation that indicates successful processing of the dye. The gallery is air-conditioned against the harsh sun of the day but the vat itself is well insulated, just like the one in the workshop.

The care could be a metaphor for indigo in the Indian culturescape right now. From the west to the east and the south to the north, this ancient dye — predominantly used for fabric in most of recorded history — is the focus of new cultivation, fresh innovations and novel applications. Indigo-dyed stone? Done. Indigo-infused metal? Patented. Indigo you can wear as a perfume? So close.

Visitors at Blue Futures: Reimagining Indigo

It might be a reach to call it the second indigo revolution, but the resurgence of interest in the Indigofera tinctoria plant is showing up in exhibitions such as Blue Futures, in textile artworks snapped up by leading collectors, in laboratories pushing the boundaries of the dye, in designer textiles, and yes, in artisanal crafts as well.

While the simultaneous showcasing can be put down to coincidence, practitioners are aware that it’s been a long time coming. Over the past couple of decades, as capitalist systems of thought and economy came under scrutiny, alternative thinkers have sought out slower, more mindful and sustainable ways of living. The growing popularity of natural dyes is only one of its manifestations.

New Horizons Weftscapes by Bappaditya Biswas(handwoven jamdani in natural indigo)

Tapestry by Takuma; (L-R) natural indigo with yatara miura shibori, and indigo on cotton with yatara miura shibori and boshi shibori

“This renewed love for natural indigo feels like a return to memory — an attempt to remember our past with care. It is also a quiet movement back towards the earth, and towards our shared sense of humanity.”Anuradha SinghDirector of Jaipur-based Nila House, an organisation working with indigo at the intersection of craft, design, sustainability and community empowerment

From growing and farming the indigo plant to fermenting and developing the pigment, each of the processes is necessarily meditative and unhurried, a delicate tango of time, skill, learning and nurture. Much of this corpus of expertise is inherited and undocumented, and there is little official effort to preserve this massive knowledge base.

Artistic entrepreneurs see this lacuna as an opportunity for an intervention. And, wiser after centuries of appropriation of Indian craft know-how, they’re ready with guardrails for their discoveries. The last is important because, as textile designer Mayank Mansingh Kaul points out, much of the research into indigo and, indeed, natural dyeing, is driven by foreign — especially Japanese — demand.

Bappaditya Biswas

Reintroduced the indigo plant in West Bengal

A textile designer, successful businessman, fabric engineer, and chintz artist. Bappaditya Biswas wears many hats, but the most recent jewel in his crown comes from reintroducing the indigo plant in Bengal. “A very strong sense of oppression and fear is still associated with indigo in eastern India,” says Biswas, of the erstwhile epicentre of the British trade in the dye in the 1800s. “In Phulia, they call it the ‘evil crop’, they said it ruined the land, they even built over the historical vats.”

Fired by the idea of a dye that could inspire a revolution — the nil bidroho (indigo revolt) of 1859 was a landmark peasant movement against the extreme cruelty of British planters looking to maximise indigo output — Biswas began researching indigo in 2006. But it was only in 2020 that he was able to convince Sanjay Pramanik, a Phulia-based master weaver for his Byloom label, to grow the plant. “For 165 years, indigo had only lived in the imagination. There isn’t even a record of the variety of indigo that grew here,” says Biswas. “We procured the seeds of the Indigofera tinctoria from Tamil Nadu (it’s an old crop there), and it took to the conditions really well. What is also encouraging is that it helped the locals discover its benefits compared to chemical dyes.”

Bappaditya Biswas in a field of indigo

At present, the indigo output is too small to take care of the demands of Byloom — about 20% of its production uses natural dyes — but Biswas puts the Phulia indigo to excellent application in the large handwoven, handspun cotton canvases he prefers for his meticulously crafted chintz art. “Chintz is also something that has been wiped out (like indigo in Bengal),” says the entrepreneur with a revivalist’s soul. “Chintz refers to a particular design pattern, yes, but it is also a technique. I wanted to find out if it could still be done the old way: with natural dyes, in a mordant-resist process.”

Chintz done the old way, with natural dyes, in a mordant-resist process

Biswas’s interest was first piqued by a large handpainted chintz from the TAPI Collection (a private collection of textile and art in Surat) in the early 2000s. He followed it up with a seven-day workshop with French-Canadian artist Michel Garcia in 2009. But it was only during the pandemic lockdown that he was able to put paint to cloth, remaking chintz with foliage, fauna and Vishnu avatars in natural dyes. Inspiration comes from childhood memories, calendar art, even holidays in North Bengal tea gardens. “It’s all an expression of my love for textiles,” he says, refusing to draw lines between his various practices. “There are all parts of my whole being coming together.”

Kavin Mehta

Uses indigo to dye natural materials such as stone

Immersion takes on new meaning at the Blue Futures show, which can make visitors feel like they are in a blue dreamscape, or in a fantastic underwater expedition, surrounded by spot-lit, surreal objects of joy. Against the twilight-darkened floor-to-ceiling windows of the gallery, however, one artwork draws every eye. It’s a large, almost rectangular stone sculpture, etched with ever lighter shades of indigo. Container, as it’s called, is a vase made of western Indian limestone (wrongly described as sandstone in the title card) and painted with natural indigo dyes — of which the limestone is also a component. The stark, evocative work gives circularity a whole new nuance.

Container, a vase made of western Indian limestone and painted with natural indigo dyes

A few feet away stands another piece, this one untitled. Reminiscent of Dutch graphic artist Escher’s puzzle-like works, it’s also crafted out of a limestone block — but this one is dyed in a single shade of indigo, its darkness throwing into sharp relief the glittering embedded silica, invisible in its natural white state.

Crafted from a limestone block

Both works are by Kavin Mehta, industrial designer and accidental artist. “I became interested in indigo as a student in the U.K. when I was researching products that get better with age; it was that metamorphosis (think how a pair of jeans reflects the shape and postures of its wearer) that really spoke to me,” says Mehta. “Back in Ahmedabad, I was building my design studio in an old mining hub called Gota, when I started tinkering with the stone around. I learnt from traditional stonemasons, that’s how I started my art practice. I tried to look at stone as space, so, Container, for instance, plays with the idea of depth in an introspective sense as well.”

Kavin Mehta

Mehta’s art brought him in touch with Sanjay Lalbhai of Arvind Ltd., one of the world’s largest denim manufacturers. Keen to initiate deeper research into his key dye in its natural form, Lalbhai set up the Indigo Art Museum in Ahmedabad in 2019 and asked Mehta to head it, with a special brief to discover indigo’s affinities with non-textile materials. Those investigations have led to 20 patents for the museum, including fusions of indigo with aluminium and leather, as well as ongoing artistic explorations.

Mehta himself also works with wood, clay, ceramics and other natural materials in conjunction with natural indigo, a process he describes as a “dialogue” with his own vision, with each element possessing its own unpredictabilities. “No chemical blue gives an artist the range indigo can. Nothing has ever challenged me like indigo — every time I think I know it, it surprises me,” he says. “As a designer, I build for longevity, not merely sustainability, and indigo resonates with that philosophy.”

11.11/eleven eleven

Learning to paint and print with indigo

That this renewal of interest in indigo has legs is clear from the research being conducted independently into various aspects of the dye. Their originators often choose to showcase their breakthroughs first as art; commercialisation, they are aware, will follow. As a part of the recent Madras Art Weekend, Chennai-based boutique Collage, for instance, exhibited an installation by craft-forward design brand 11.11/eleven eleven to mark their formulation of indigo paste.

Collage and 11.11/eleven eleven at Madras Art Weekend

| Photo Credit:

Rangaprasad

“Indigo has always been used as dip-dye — 100% natural indigo cannot be used for printing. But we like to paint and print with natural dyes,” says Shani Himanshu, co-founder of the 16-year-old label, pointing out that till date, a chemical reduction would be necessarily added to natural indigo to allow printing. (This is also the reason commonly available indigo prints get a bad rap for bleeding, rubbing and fading, since the chemical process makes it susceptible to oxygen.)

Shani Himanshu

“The question was, how can we keep indigo in a reduced form naturally. After years of R&D, we discovered the answer in indigo paste. It uses a natural binder, which is our intellectual property, and the moment it reacts with water, it oxidises and turns blue.”

Coming on the back of two decades of experimenting with indigo, 11.11/eleven eleven is one of the few textile enterprises (if not the only one) to have their own vats, capable of fermenting 5,000 litres of natural dye in their New Delhi studio. The research was aimed at ensuring all-round safety for the artisans who would be working with the material, says Himanshu. “We also believe what you wear should breathe with you, it should be good for you,” he adds. “Indigo is a medicinal plant, it has many beneficial properties.”

The 11.11/eleven eleven installation at Collage (first launched at their Mumbai store opening last year) encapsulated this participatory idea by displaying tapestries created when people walked through indigo paste onto large canvases, ‘painting’ it, so to say, with their feet. Each piece is thus unique and distinct. This is exactly the spirit that, Himanshu hopes, will be carried forward as artists, designers and textile practitioners make the stabilised indigo paste their own.

11.11/eleven eleven at Madras Art Weekend

“Much like ikat, indigo is a medium for us in India to connect with the world. Africa has indigo, as do other parts of Asia. The next stage for us as curators is to start looking at connections that Indian textiles have with other parts of the world, especially the Asia-Africa paradigm.”Mayank Mansingh Kaul Textile designer, writer and curator

Mayank Mansingh Kaul

| Photo Credit:

Courtesy the Baldota Foundation

Visalakshi Ramaswamy

Adding blue to Chettinad’s palm leaf basketry

Back in 2000, when Visalakshi Ramaswamy established the M.Rm.Rm. Cultural Foundation to work with the local cultural heritage of Chettinad, she chose kottan, the woven palmyra leaf basket traditional to the region, as her first project. A quarter century and many other initiatives later, it continues to be the product the Foundation is best known for. But Ramaswamy is not satisfied.

Visalakshi Ramaswamy

“We started the kottan project to generate employment for village women. Palm is locally available but, for most of the lifespan of the project, we’ve had to use chemical colours as they were the only option,” says Ramaswamy. “A few years ago, we started experimenting with natural dyes, they seemed more in keeping with the ethos of the raw material. While we’ve been able to produce 28 colours with natural dyes, indigo has proved to be a challenge.”

About a year ago, the Foundation reached out to the Indigo Art Museum for help. “We thought it would be great to take it up because the leaf has some inherent properties we hadn’t worked with,” says Kavin Mehta, the lead on the research project. “They wanted to display indigo basketweaves at their 25th anniversary exhibition, and we managed to deliver. But we knew we could improve the process. Developing an easy-to-use kit for the artisans, to my mind, is an even bigger challenge.”

Dyeing palm leaves

| Photo Credit:

Courtesy M.Rm.Rm. Cultural Foundation

The chief issue Mehta’s eight-member R&D team faced with the palm leaf was its hydrophobic nature: as a water-proximate plant, it is naturally resistant to moisture, which includes the indigo dye. The next step was preparing a dye vat with affinities towards the raw material. After the washing and the final fixing, the leaf also needs to retain its natural malleability for the weaving. Though the team has achieved some success with the colour, the artisans are not happy with the brittleness of the indigo-dyed leaf.

But Mehta is not about to give up either. And so, hopefully some day not too far in the future, the palm leaf kottan, in addition to the yellows, greens, reds and blacks it is already available in, will also turn a brilliant blue.

Kottan weavers at work

| Photo Credit:

Catherine Karnow

Ally Matthan

Making an ‘earthy, dense and green’ indigo perfume

In 2019, entrepreneur Ally Matthan was in an IIM-Ahmedabad classroom, trying to conceptualise a perfume project. “Every single idea I put out was scuttled. Anchal Jain, co-chair of the Creative and Cultural Businesses Programme, kept urging me to look within,” she remembers. “By then, I was deeply embedded in the indigo community through textiles (as founder of the research-driven Registry of Sarees). And I think that’s what led to my experiments with the indigo plant for a perfume.”

Ally Matthan

| Photo Credit:

Chaitali Paranjape

A graduate of ISIPCA (Institut Supérieur International du Parfum, de la Cosmétique et de l’Aromatique Alimentaire), Versailles, Matthan believes fragrance is a way for her to “sensorially understand the depth and soul of indigo”. She explains, “In the Indian system — think attars — the process of extraction is very different from modern methods. The language reflects it too; the essential oils (derived through steam distillation) are the rooh, the soul.”

Over the lockdown years, Matthan started growing her own indigo on the outskirts of Bengaluru and has, since then, experimented steadily to arrive at its perfect aromatic representation. “Different crop cycles have, at different times, given us different extractions — that is why we have spent so long in development,” she says, naming Ashok Siju of Jeevan Indigo, Kutch, and Jesus Ciriza Larraona of Colours of Nature, a natural dye house in Auroville, as her mentors through the process. “I like working with the roots and stem of the plant — the leaves produce a scent that’s similar but not the same — and blend the essential oils thus extracted with other ingredients to provide the complete indigo experience, the closest reflection of my own immersion in indigo.”

Ask Matthan to describe the fragrance — scheduled to roll out in the next four to five months — and the adjectives roll off her tongue: earthy, woody, amber, dense and green, while also being humid and wet. “I also think, as much as there is lightness about indigo, there’s also a darkness,” she says. “Indigo is not a fragrance by itself, it comes with a context and a subtext. If the colour is its personality, I feel the fragrance is its soul.”

Blue Futures: Reimagining Indigo will be on show at Hampi Art Labs till January 28, 2026.

The writer and editor is based in Bengaluru.